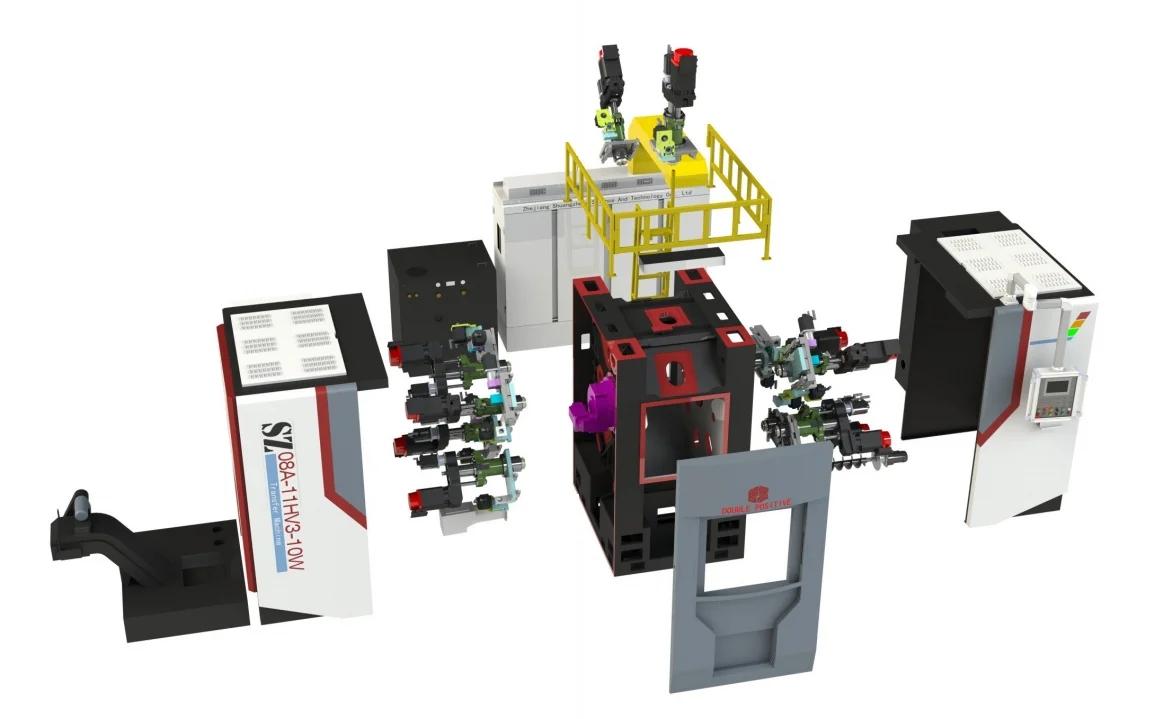

In the application of high-performance and high-precision integrated transfer machine, in order to achieve stability and good processing efficiency, the general integrated transfer machine machining tools are higher than the requirements of ordinary tools in design, manufacturing and use. The main difference between machining tools and ordinary tools is in the following aspects:

1, high precision manufacturing quality

In order to stabilize the surface of high-precision parts, therefore, the requirements of the manufacturing of tools (including tool parts) in terms of accuracy, surface roughness, form and position tolerance are more stringent than those of ordinary tools, especially indexable tools, in order to ensure the repeated accuracy of the tool tip (turning edge) size after transposition. The size, accuracy and surface roughness of the key parts of the cutter body, such as the cutter groove and positioning parts, must be strictly guaranteed. At the same time, in order to facilitate the tool and size measurement in the tool instrument, the machining accuracy of the base surface should also be ensured.

2, tool structure optimization

Advanced tool structure can greatly improve the cutting efficiency, such as high-speed CNC milling cutter in the structure has more waveform and large spiral Angle structure, cooling using carbide indexable tools, blade installation removable adjustable structure, modules, such as internal cooling structure, is ordinary machine tools can not be applied. CNC hardware processing equipment

3, the wide application of high-quality materials

In order to extend the service life of the tool and improve the strength of the tool, many integrated transfer machine processing tool materials use high-strength alloy steel blades, and heat treatment (such as nitriding surface treatment), which can make it suitable for large cutting with less consumption. It can also significantly improve the service life of the tool (the common tool is the tempered tool of medium carbon steel). In terms of cutting edge materials, integrated transfer machine machining tools use more of a variety of new grades of cemented carbide (fine particles or ultra-fine particles) and superhard tool materials.

4, does not affect the normal work of the chip-breaker selection

The tool used by the integrated transfer machine has strict requirements for the chute. During processing, the tool is often unable to work normally by the chip removal machine (some integrated transfer machine, turning in the off state), so whether the integrated transfer machine, milling machine, drilling machine or boring machine, The blades are optimized for different processing materials and procedures without affecting the normal operation of the chip discharge groove, so that the turning can be stable chip breaking. CNC hardware processing equipment

5, surface coating treatment

The emergence and development of surface coating technology is mainly due to the emergence and development of integrated transfer machine tools. Because the coating can significantly improve the hardness of the tool, reduce friction, improve the turning efficiency and service life, more than 80% of the coating technology is used in the machining of various cemented carbide indexable integrated transfer machine tools.

integrated transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html